青海ZJW Feed Pump for Filter Press

订购电话:166-0318-1010

发布时间:2019-07-01 17:36:13

产品说明:

I. Features of ZJW Dedicated Feed Pump for Filter PressInnovative Design: Novel hydraulic and structural design ensures high efficiency, abrasion resistance, and stable, reliable operation.Dual-Stage Performance:Early-stage feeding: Delivers large flow ra

I. Features of ZJW Dedicated Feed Pump for Filter Press

II. Brief Description of ZJW Dedicated Feed Pump for Filter Press

The ZJW dedicated feed pump for filter presses draws slurry from the rear side and employs a simple packing seal without leakage. Its steep flow-head curve makes it ideally suited for filter press applications.

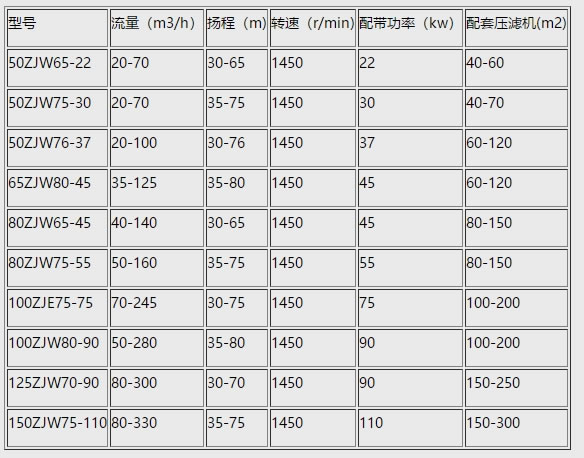

Selection of ZJW Dedicated Feed and Pressurizing Pump for Filter Press:

The ZJW pump is a pressurized suction pump with a limited suction lift. It is recommended that the feeding liquid level be higher than the pump’s centerline. The diameters of the inlet and outlet pipelines are generally the same as or slightly larger than the pump’s ports. Given the typically high slurry concentration, the inlet pipeline should not be excessively long to avoid affecting suction performance.

III. Selection of ZJW Dedicated Feed Pump for Filter Press

The selection of the ZJW pump differs significantly from general conveying pumps. For general pumps, selection focuses on a specific point or short segment of the flow-head curve. However, the filter press operates with a gradually forming filter cake in the chamber, leading to increasing feeding resistance. The feed pump must transition from high flow and low head at the start to low flow and high head at the end of filtration. This requires a pump with a long, preferably steep flow-head curve. Additionally, the pump must operate under high pressure without shaft seal water and with zero leakage, facilitating the establishment of environmentally friendly facilities.

IV. Power Configuration of ZJW Dedicated Feed Pump for Filter Press

The maximum power consumption of the feed pump occurs during the initial feeding stage. Therefore, it is crucial to calculate the minimum pressure required to inject slurry into the filter press and select the pump power based on the corresponding flow and head at this minimum pressure. This approach ensures accurate and energy-efficient power configuration.

Due to variations in the actual layout of filter press systems across factories, significant frictional resistance in the pipeline between the feed pump and filter press (e.g., long pump-to-filter distance, undersized pipes, numerous elbows and valves, high slurry viscosity) can increase head loss, reduce cake-forming pressure, and lead to higher moisture content in the filter cake and prolonged cycle times. To maintain system efficiency, proper pipeline configuration is essential.

Due to the wide variety of product specifications and models, our company provides only partial parameters. For more detailed information, please contact our technician at 182-3296-2233.

推荐资讯

青海slurry pump

- 青海SP and SPR slurry pumps

- 青海AH/HH slurry pump

- 青海ZJ series slurry pumps

- 青海ZJQ slurry pump

- 青海ZJL Submerged Slurry Pump

- 青海ZGB Slurry Centrifugal Pump

- 青海Submerged slurry pump

- 青海Horizontal slurry pump

- 青海Foam pump

- 青海Submersible slurry pump

青海mud pump

- 青海PN mud pump

- 青海PNL Mud Pump

- 青海NL mud pump

- 青海Marine mud pump

- 青海Submersible mud pump

- 青海Submerged mud pump

- 青海Petroleum mud pump

青海Chemical pump

- 青海化工流程泵

- 青海化工循环泵

- 青海耐盐酸离心泵

- 青海IH型化工泵

- 青海氟塑料化工泵

- 青海衬氟化工离心泵

- 青海FZB氟塑料自吸泵

- 青海卧式化工离心泵

- 青海不锈钢化工离心泵

- 青海耐腐蚀不锈钢离心泵

- 青海无泄漏衬氟塑料离心泵

青海Feed pump for filter press

- 青海SYA Feed Pump for Filter Press

- 青海ZJE Type Feed Pump for Filter Press

- 青海ZJW Feed Pump for Filter Press

- 青海plate and frame filter press

- 青海environmental protection filter press pump

- 青海Specialized Pump for Coal Washing Plants

- 青海Filter Press Feed Pump

- 青海Plate and Frame Filter Press

青海Pipeline pump

联系我们

24小时服务热线166-0318-1010- 联系人: Mr. Zhang

- 公司地址: It is located 1000 meters north of Houzhangzhuang Village, Anping Town, Anping County.