Horizontal slurry pump

订购电话:166-0318-1010

发布时间:2019-06-25 16:55:05

产品说明:

【Friendly Reminder】: Due to the different product models, the parameters and prices of each model vary, and it is impossible to fully display them on this page. If you have any questions, you are welcome to contact our customer service to inquire about

【Friendly Reminder】: Due to the different product models, the parameters and prices of each model vary, and it is impossible to fully display them on this page. If you have any questions, you are welcome to contact our customer service to inquire about the model and price. Thank you for your patronage!

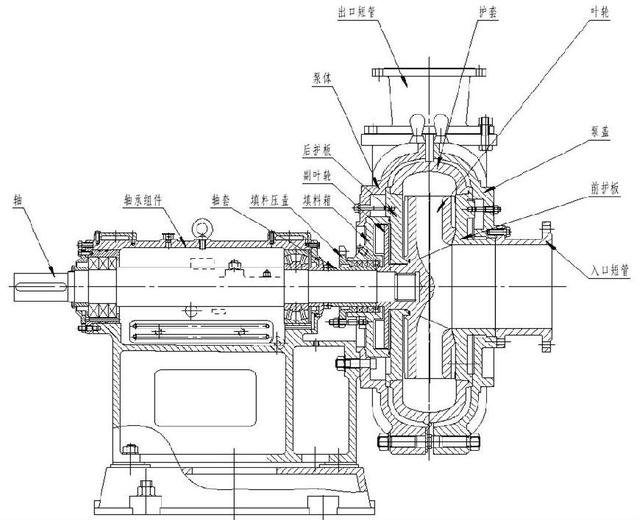

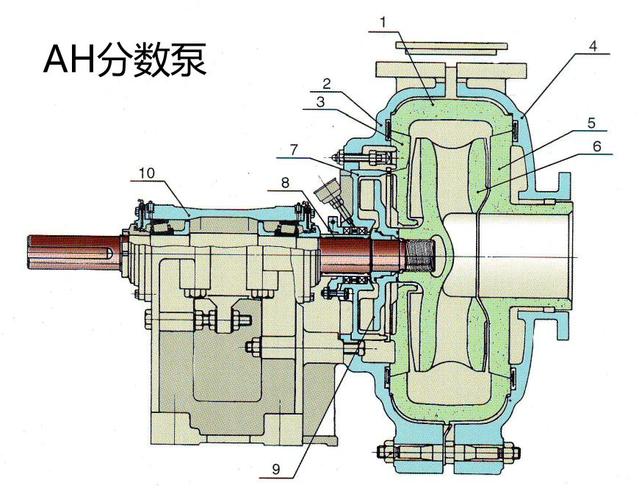

The horizontal slurry pump is a cantilever centrifugal slurry pump suitable for conveying abrasive or corrosive slurries. Except for the different structures of the pump head part (including the pump body, pump cover, impeller, etc.), the structures of other parts of various types of horizontal slurry pumps are similar. The following describes the structural characteristics of the pump head part, shaft seal part, and transmission part respectively.

Structural characteristics of the horizontal slurry pump

1. Pump head part

2. Shaft seal part

3. Transmission part

All types of horizontal slurry pumps use the same series of transmission parts, including the bracket and bearing assembly. The pump shaft has a large diameter, good rigidity, and a short cantilever, and will not bend or vibrate under harsh working conditions. Depending on the transmitted power, heavy - duty single - row or double - row tapered roller bearings and cylindrical roller bearings are selected for the bearings, which can withstand the large axial and radial loads of the pump. The bearings are lubricated with grease. There are sealing end covers, labyrinth sleeves, and labyrinth rings at both ends of the bearing body, which can effectively prevent dirt such as pulp from entering the bearings, ensuring the safe operation of the bearings and a long service life.

Transmission types: DC direct - drive transmission, CR parallel belt drive, ZVZ upper - and - lower belt drive, CV vertical belt drive, etc. By adopting a variety of speeds and multiple modification methods, the pump can operate under the optimal working conditions. It has a long service life, high operating efficiency, and can meet various harsh conveying conditions.

Advantages of the horizontal slurry pump

Due to the large number of models of horizontal slurry pumps, and with limited space on the product page, we can only use the parameters of one model as a reference. If you need other product models, you can contact our factory's technician at 182-3296-2233!

型号 | 轴功率P(Kw) | 清水性能 | 叶轮 直径D(mm) | 重量Wt.(kg) | ||||

流量Q(I/s) | 扬程H(m) | 转速n(r/min) | *高效率η% | 汽蚀余量NPSH(m) | ||||

ZGB(P)65 | 28.8-19.9 | 31.7-15.8 | 58-61 | 1480 | 62.5-47.4 | 4.5-3.0 | 390 | 1850 |

8.37-5.8 | 21.0-10.5 | 25.4-26.7 | 980 | 62.5-47.4 | 2.0-1.3 | |||

ZGB(P)80 | 73.7-52.2 | 56.7-28.3 | 87.5-91.6 | 980 | 66.1-48.7 | 5.2-2.7 | 485 | 2500 |

21.4-15.2 | 37.5-18.8 | 38.4-40.2 | 740 | 66.1-48.7 | 2.3-1.2 | |||

56.8-40.4 | 52.0-26.0 | 73.7-77.1 | 980 | 66.1-48.7 | 4.4-2.3 | 445 | ||

16.5-11.7 | 34.4-17.2 | 32.3-33.8 | 740 | 66.1-48.7 | 1.9-1.0 | |||

41.3-29.2 | 46.8-23.3 | 59.5-62.3 | 980 | 66.1-48.7 | 3.5-1.8 | 400 | ||

12.0-8.4 | 31.0-15.4 | 26.1-27.3 | 740 | 66.1-48.7 | 1.5-0.8 | |||

ZGB(P)100 | 124.9-91.4 | 116.7-58.3 | 85.1-91.8 | 1480 | 77.9-57.4 | 6.0-2.6 | 500 | 3000 |

36.3-26.6 | 77.3-38.6 | 37.3-40.3 | 980 | 77.9-57.4 | 2.7-1.2 | |||

91.0-66.7 | 105-52.5 | 68.9-78.4 | 1480 | 77.9-57.4 | 4.9-2.1 | 450 | ||

26.4-19.4 | 69.5-34.8 | 30.2-32.6 | 980 | 77.9-57.4 | 2.1-1.1 | |||

64.0-46.9 | 93.4-46.7 | 54.5-58.8 | 1480 | 77.9-57.4 | 3.8-1.7 | 400 | ||

18.6-13.6 | 61.8-30.9 | 23.9-25.8 | 980 | 77.9-57.4 | 1.7-0.8 | |||

ZGB(P)150 | 215.0-165.5 | 200-100 | 85.2-90.0 | 980 | 77.7-53.3 | 3.8-2.7 | 740 | 3450 |

92.7-71.3 | 151.2-75.6 | 48.6-51.3 | 740 | 77.7-53.3 | 2.2-1.5 | |||

168.0-129.3 | 182.4-91.2 | 73.0-77.1 | 980 | 77.7-53.3 | 3.3-2.3 | 685 | ||

74.2-56.8 | 140.0-70.2 | 41.6-44.0 | 740 | 77.7-53.3 | 1.9-1.3 | |||

131.9-101.5 | 169.2-84.6 | 61.8-65.2 | 980 | 77.7-53.3 | 2.8-1.1 | 630 | ||

57.6-44.3 | 129.6-64.8 | 35.2-37.2 | 740 | 77.7-53.3 | 1.6-0.6 | |||

ZGB(P)200 | 342.9-219.1 | 300.0-150.0 | 89.0-94.2 | 980 | 76.3-63.2 | 6.7-2.7 | 740 | 4000 |

147.5-97.3 | 226.5-113.3 | 50.7-53.7 | 740 | 76.3-63.2 | 3.8-1.5 | |||

290.2-185.8 | 283.8-141.9 | 79.6-84.3 | 980 | 76.3-63.2 | 6.0-2.4 | 700 | ||

125.0-80.0 | 214.3-107.1 | 45.4-48.1 | 740 | 76.3-63.2 | 3.4-1.4 | |||

222.0-141.8 | 259.5-129.7 | 66.6-70.5 | 980 | 76.3-63.2 | 5.0-2.0 | 640 | ||

95.6-61.0 | 195.9-97.9 | 38.0-40.2 | 740 | 76.3-63.2 | 2.9-1.1 | |||

ZGB(P)250 | 421.2-275.6 | 400.0-200.0 | 84.0-90.1 | 980 | 78.2-63.2 | 7.3-3.3 | 740 | 4500 |

181.4-118.7 | 302.0-151.0 | 47.9-51.4 | 740 | 78.2-63.2 | 4.2-1.9 | |||

356.7-233.2 | 378.4-189.2 | 75.2-80.6 | 980 | 78.2-63.2 | 7.1-3.0 | 700 | ||

153.7-100.5 | 285.7-142.9 | 42.9-46.0 | 740 | 78.2-63.2 | 4.0-1.7 | |||

278.8-137.9 | 348.6-131.6 | 63.8-68.5 | 980 | 78.2-63.2 | 5.5-2.5 | 645 | ||

120.1-59.4 | 263.2-99.4 | 36.4-39.1 | 740 | 78.2-63.2 | 3.1-1.4 | |||

ZGB(P)300 | 542.8-357.6 | 533.3-266.7 | 84.3-93.4 | 980 | 81.2-68.3 | 6.9-3.5 | 760 | 5500 |

233.9-154.0 | 402.7-201.3 | 48.1-53.3 | 740 | 81.2-68.3 | 3.9-2.0 | |||

429.4-282.9 | 493.3-246.7 | 72.1-79.9 | 980 | 81.2-68.3 | 5.9-3.0 | 703 | ||

184.8-116.4 | 372.5-177.9 | 41.1-45.6 | 740 | 81.2-68.3 | 3.4-1.7 | |||

333.3-219.7 | 453.3-226.7 | 60.9-67.5 | 980 | 81.2-68.3 | 5.0-2.5 | 646 | ||

143.4-94.6 | 342.3-171.2 | 34.5-38.5 | 740 | 81.2-68.3 | 2.9-1.4 | |||

推荐资讯

slurry pump

- SP and SPR slurry pumps

- AH/HH slurry pump

- ZJ series slurry pumps

- ZJQ slurry pump

- ZJL Submerged Slurry Pump

- ZGB Slurry Centrifugal Pump

- Submerged slurry pump

- Horizontal slurry pump

- Foam pump

- Submersible slurry pump

mud pump

- PN mud pump

- PNL Mud Pump

- NL mud pump

- Marine mud pump

- Submersible mud pump

- Submerged mud pump

- Petroleum mud pump

Chemical pump

Feed pump for filter press

- SYA Feed Pump for Filter Press

- ZJE Type Feed Pump for Filter Press

- ZJW Feed Pump for Filter Press

- plate and frame filter press

- environmental protection filter press pump

- Specialized Pump for Coal Washing Plants

- Filter Press Feed Pump

- Plate and Frame Filter Press

Pipeline pump

联系我们

24小时服务热线166-0318-1010- 联系人: Mr. Zhang

- 公司地址: It is located 1000 meters north of Houzhangzhuang Village, Anping Town, Anping County.